Client

Nikola Motor Company is on a mission to transform and disrupt the transport industry on a global scale. They design and manufacture Battery-electric (BEV) and Hydrogen fuel-cell (FCEV) vehicles, vehicle components, energy storage systems, and electric vehicle drivetrains.

Nikola has developed several different vehicles, putting an emphasis on performance, and working towards complete zero-emissions, from production to consumption of energy.

Requirements & Context

Nikola wanted to differentiate from the rest of the automotive industry with a more efficient and sustainable approach to service support and reimagined solutions for common service needs including 360 connectivity with real-time remote diagnostics, a growing nationwide network of service centers and part suppliers, and a comprehensive component and base warranty package. The goal was that customers could count on Nikola to keep their trucks on the road.

To deliver this level of service, providers in Nikola’s network used to rely on multiple portals to interact with the OEM (original equipment manufacturer) and require specific services, parts, or warranty-related transactions. That led to a fragmented experience, not to mention it raised the OEM’s costs in terms of operation, maintenance, and development.

The main objective of this project was to create a streamlined one-stop-shop portal for dealers that allowed smoother interactions with Nikola to support the process of trucks getting serviced and put back on the road.

This service portal was meant to be a place where:

- Service support providers could perform warranty, service, and parts-related transactions

- The Nikola service team could live-monitor vehicles and respond to truck incidents

Approach

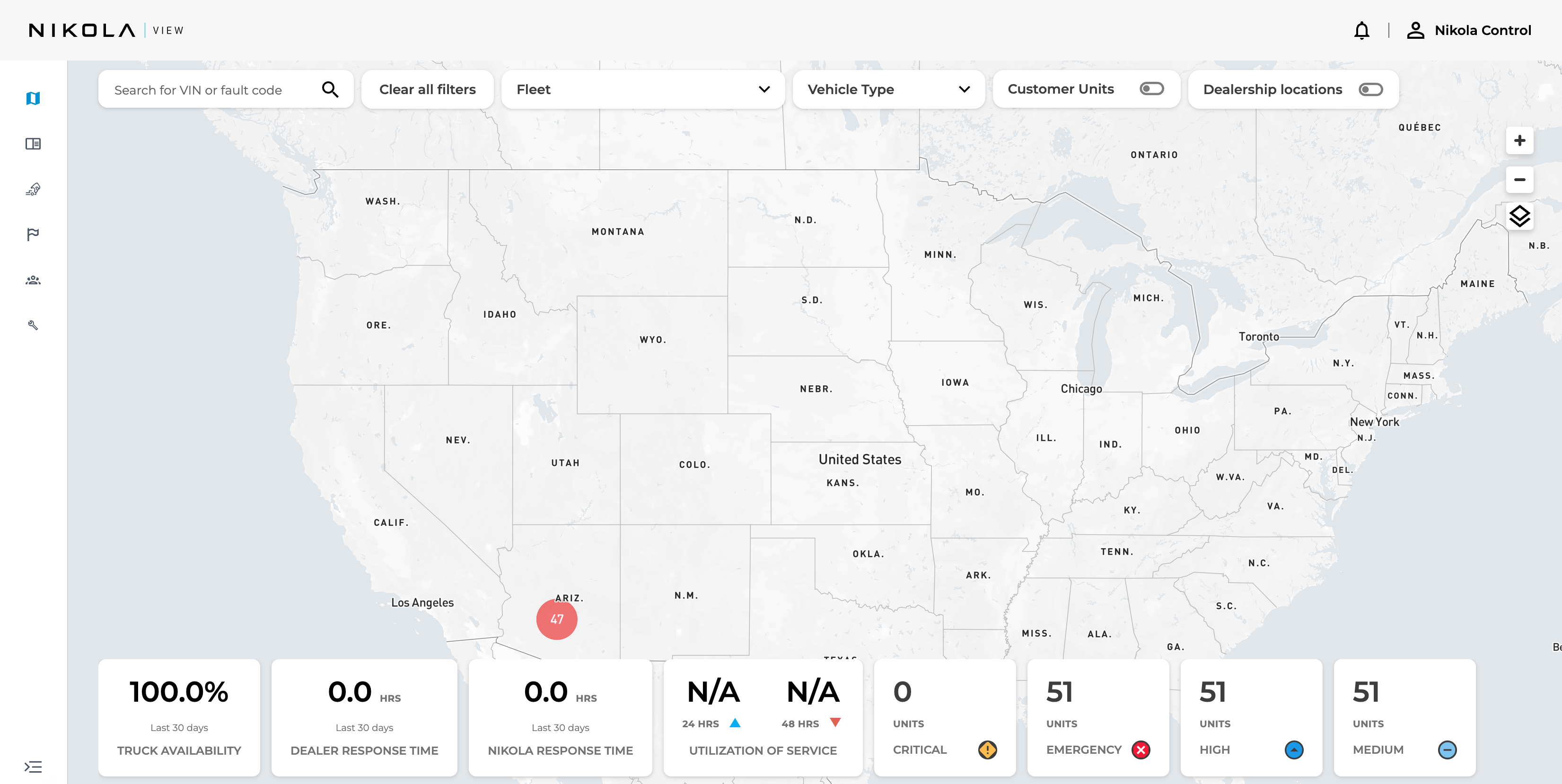

The first thing we tackled when we joined the project was a series of map integration issues, to enable the powerful visuals that deliver key information to the service support teams, improving the service availability for units on the road, by providing live monitoring of vehicle performance, showing information like speed, battery state of charge, odometer, temperature, etc.

Along with improving the dashboard’s efficiency, we also worked on the creation of filters for the map and other views, such as the list of vehicles on the road, or the list of cases open by the service support team, control room users (ie. Nikola) and Dealerships users. Another important issue was the vehicle's fault data synchronization from the Telematics system. This had to be implemented in the most efficient way possible so that information was available to users in real time.

The service portal was built on Rails 7 and Hotwire, using Mapbox for creating maps, and PostgreSQL and Redis for our databases.

Results

The Service Portal presents an interactive dashboard (Map; Reporting; Units, Cases lists, etc.) that gives Nikola’s service support team detailed information, with relevant and timely data that allows them to know the status of every vehicle, actions required to provide the highest level of service, and tracking data to maximize their supply chain’s ability to swiftly deliver parts where they are most needed.

Map

The Map component shows information about the truck’s current status (for example: position, related faults, etc.) and also statistical information.

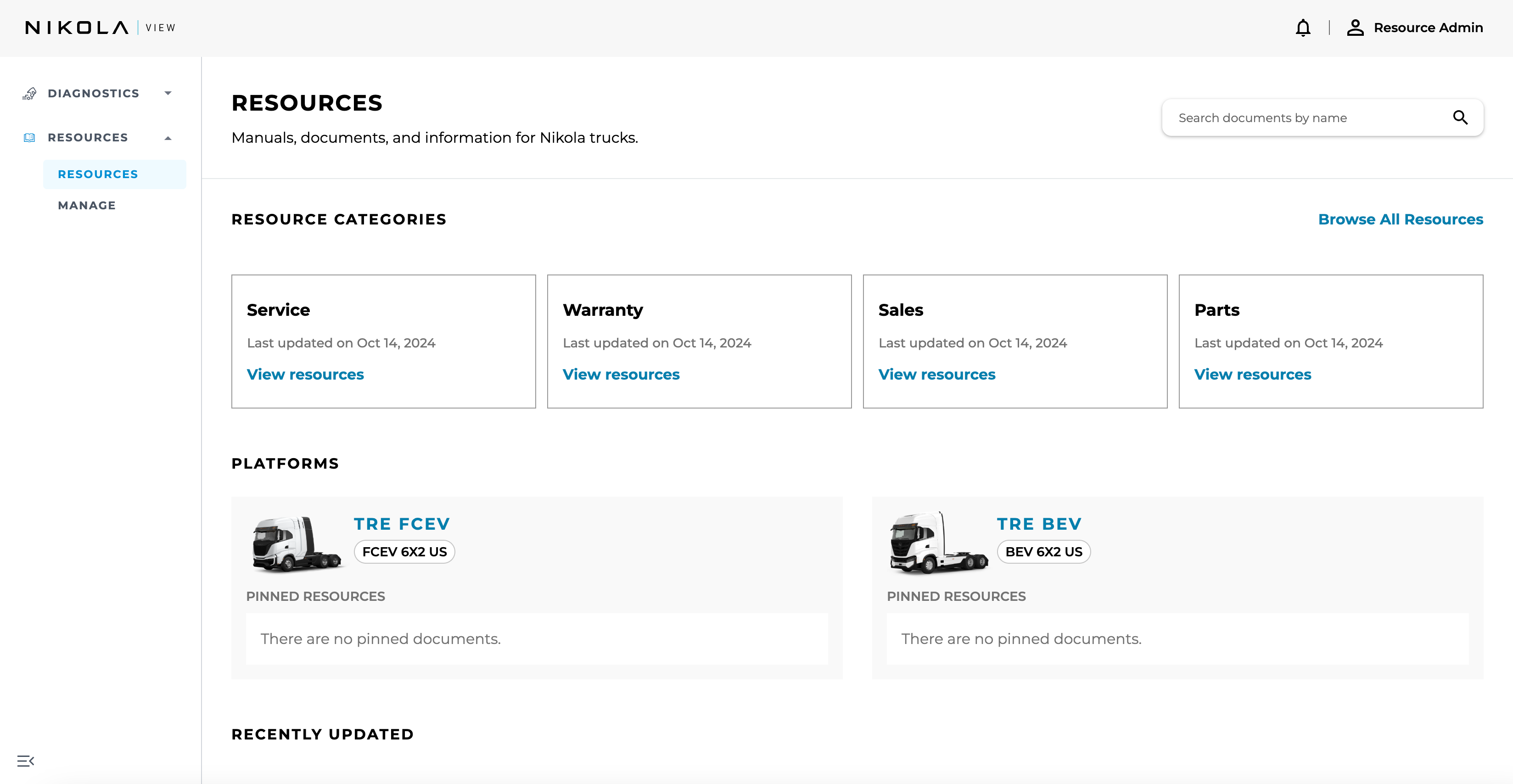

Rersources

The Resources screen groups documents and other information into different categories and also by platforms, for quick diagnostics.

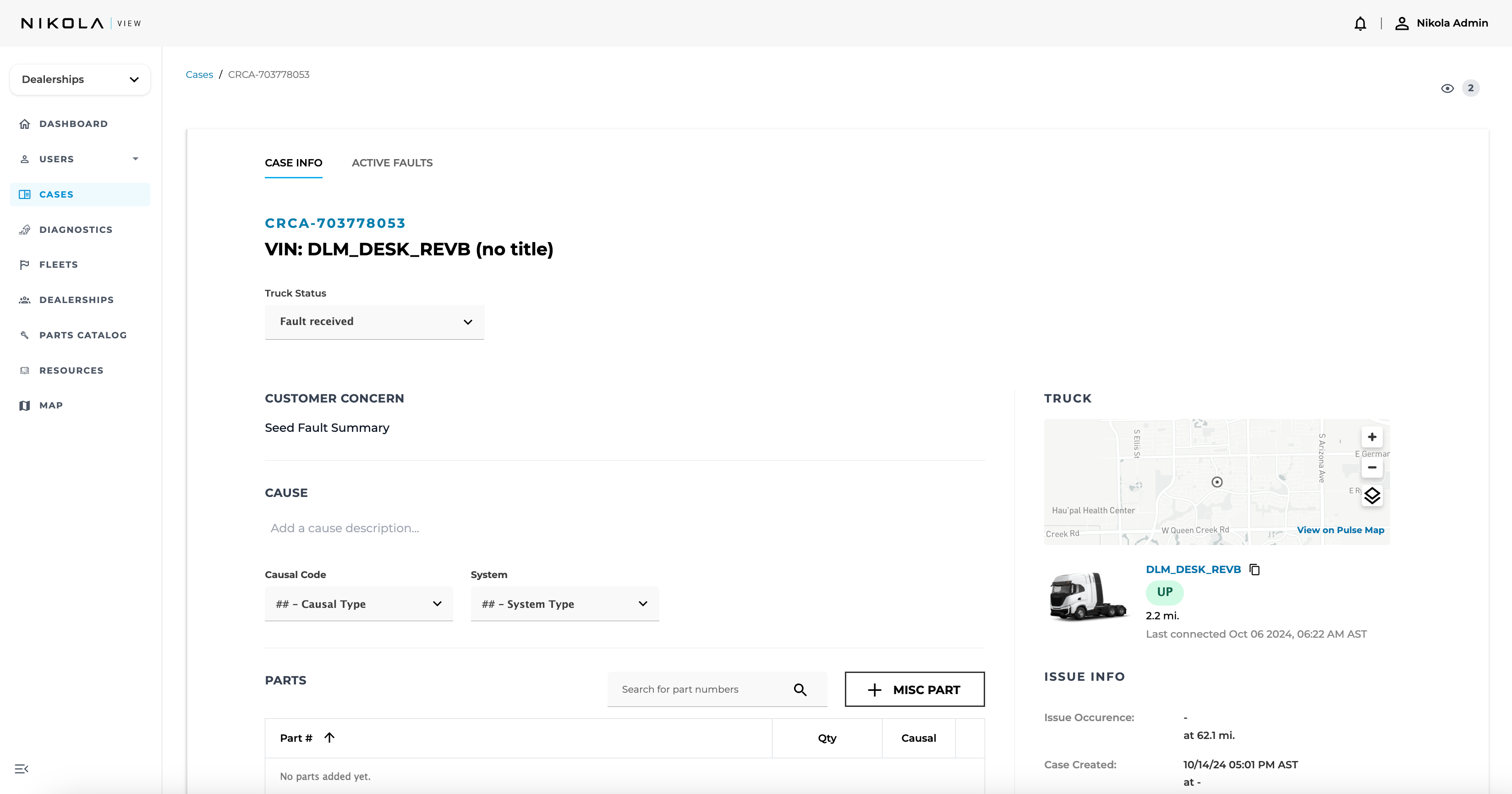

Case info

The Case component displays information about a specific case (truck status, cause for the incidence, etc.) and also the list of active faults related to the case creation.

Contributors

Francisco Tarulla Alumni

Diego Liberman CEO

Diego Duarte Full-stack Engineer

Johannes Muller Principal Engineer

Julien Portalier Principal Engineer

Bolo Michelin Alumni

Caspian Baska Alumni

Carlos Stutz Zillner Alumni